Thermal printers are popular devices used for printing receipts, labels, and barcodes due to their speed, efficiency, and low maintenance requirements. They operate on a simple yet effective principle that involves heat and specially coated paper.

1. Types of Thermal Printing

- Direct Thermal Printing: This method uses heat-sensitive paper that darkens when exposed to a heat source. The print head heats specific areas of the paper to create images and text.

- Thermal Transfer Printing: In this method, a thermal ribbon coated with wax or resin is heated by the print head, transferring the ink onto the paper. This process is used for producing more durable and long-lasting prints.

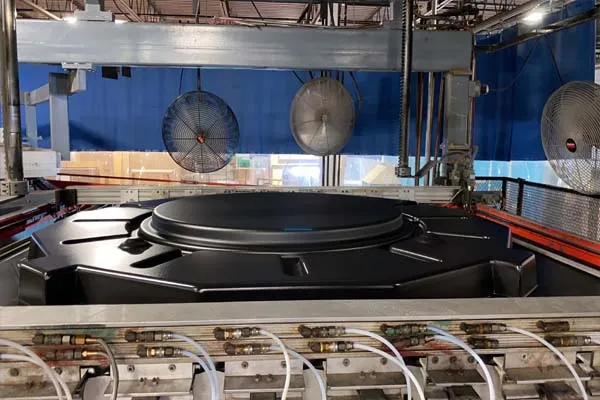

2. Components of a Thermal Printer

- Print Head: This is the most critical component, containing tiny heating elements. In direct thermal printers, it heats the paper directly. In thermal transfer printers, it heats the ribbon.

- Thermal Paper or Ribbon: Direct thermal printers use special heat-sensitive paper, while thermal transfer printers use a ribbon that melts onto the surface of the paper.

- Control Circuitry: This manages the operation of the printer, interpreting the data sent from the connected device and controlling the print head’s heating elements.

- Feed Mechanism: This moves the paper or ribbon through the printer at a consistent speed.

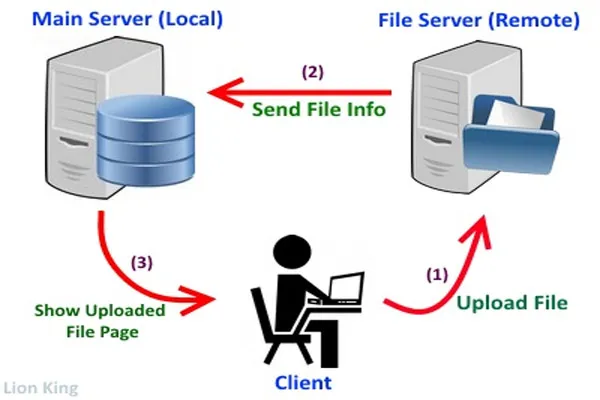

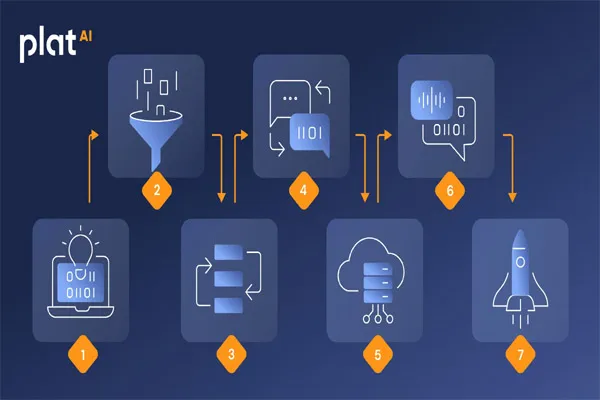

3. Printing Process

- Data Reception: The printer receives data from a computer or point-of-sale system.

- Image Processing: The control circuitry processes this data and determines how the print head should heat the paper or ribbon.

- Heating Elements Activation: The print head’s heating elements are activated in a pattern that corresponds to the data. In direct thermal printing, the paper darkens where heat is applied. In thermal transfer, the heated ribbon releases ink onto the paper.

- Paper Advancement: The feed mechanism moves the paper or ribbon forward after each print pass, allowing for continuous printing.

- Final Output: The printed document is ejected, ready for use.

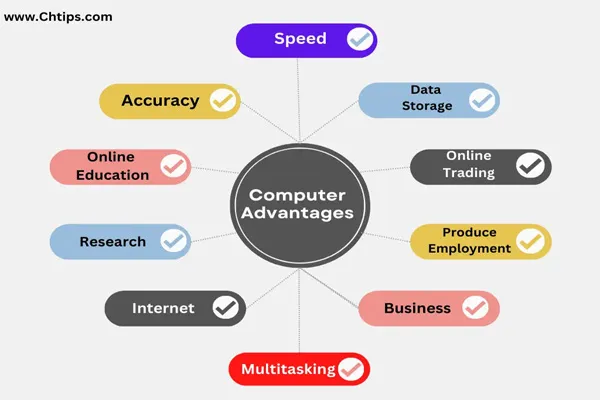

4. Advantages of Thermal Printing

- Speed: Thermal printers can produce prints quickly, making them ideal for high-volume environments.

- No Ink Cartridges: Since they use heat rather than ink, they require less maintenance and eliminate the need for ink cartridges.

- Durability: Thermal transfer prints are more resistant to fading and smudging compared to traditional ink prints.

5. Applications

Thermal printers are widely used in various industries, including retail (for receipts), logistics (for shipping labels), healthcare (for patient wristbands), and more.

Thermal printers offer a reliable and efficient way to produce high-quality prints. Their straightforward operation and low maintenance make them a favored choice across many applications, from point-of-sale systems to industrial labeling. Understanding how they work can help users make the most of these versatile devices.